Are you facing a decline in customer loyalty and employee morale? You’re not alone, and there’s a proven process that can help you turn things around.

Initially introduced by Bill Smith at Motorola in 1980, Six Sigma has become a critical tool for companies looking to improve their processes and achieve outstanding results.

Companies like Tesla have used Six Sigma methodologies to address significant challenges, such as production issues with the Model 3, helping them avoid bankruptcy and thrive.

This guide will walk you through the two primary Six Sigma methodologies: DMAIC and DMADV.

These frameworks will help reduce your organization’s time, defects, and variability, leading to higher customer satisfaction and employee morale.

Understanding the Two Six Sigma Methodologies: DMAIC & DMADV

DMAIC: For Improving Existing Processes

DMAIC is a data-driven quality strategy used to improve processes. It’s ideal for enhancing existing products or services. Here’s how you can implement DMAIC in your organization:

- Define

- Objective: Identify the problem, project goals, and customer (internal and external) requirements.

- Action: Gather insights from stakeholders and create a project charter to define the scope and objectives.

- Measure

- Objective: Collect data on the current process performance.

- Action: Use statistical tools to measure key aspects of the current process, identifying baseline performance and problem areas.

- Analyze

- Objective: Identify the root cause(s) of defects and issues.

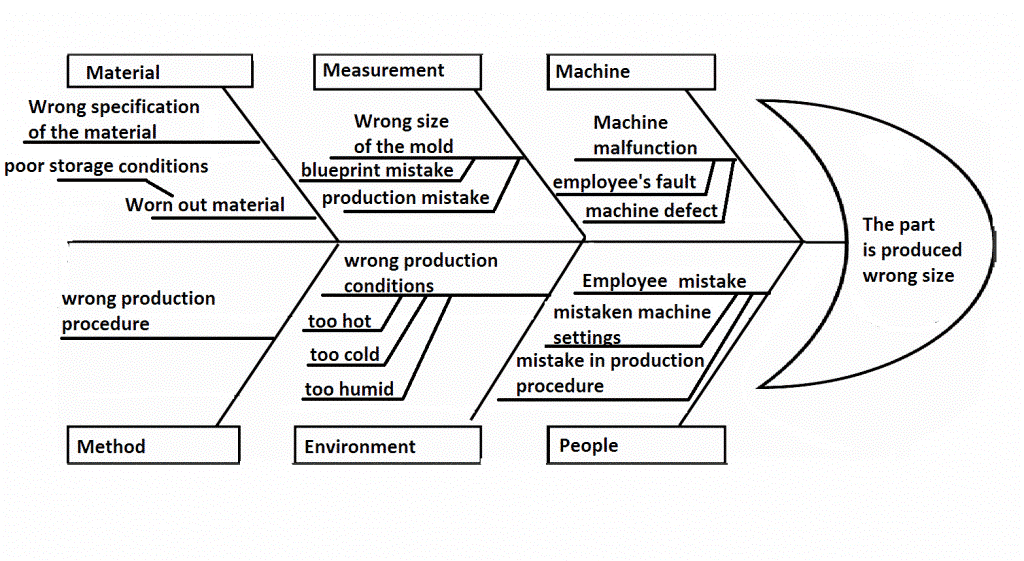

- Action: Analyze the data to uncover the root causes of defects and inefficiencies. Techniques like fishbone diagrams and regression analysis can be helpful.

- Improve

- Objective: Develop and implement solutions to address root causes.

- Action: Design and test potential solutions. Implement the best solutions to address the root causes identified in the analysis phase.

- Control

- Objective: Sustain improvements over time.

- Action: Implement control systems to monitor the process and ensure that improvements are maintained. Use control charts and regular audits to track performance.

DMADV: For Designing New Processes

DMADV, or DFSS (Design For Six Sigma), creates new processes or products that meet customer requirements. Here’s how to apply DMADV:

- Define

- Objective: Define the project goals and customer requirements.

- Action: Conduct market research, collect customer feedback, and analyze industry trends to understand customer needs.

- Measure

- Objective: Determine customer needs and specifications.

- Action: Develop detailed specifications and performance requirements for the new product or process. Use QFD (Quality Function Deployment) tools to align specifications with customer needs.

- Analyze

- Objective: Analyze the options to meet the specifications.

- Action: Evaluate different design options and identify the best approaches. Use simulations and modeling to predict performance and identify potential issues.

- Design

- Objective: Design the process or product.

- Action: Develop detailed designs, prototypes, and models. Refine the design through iterative testing and validation.

- Verify

- Objective: Verify the design meets customer needs and specifications.

- Action: Conduct final testing and validation. Launch the product or process and gather customer feedback to ensure it meets or exceeds expectations.

When to Use Six Sigma Tools

Six Sigma tools are versatile and can be used in various situations, including:

- Starting a new improvement project

- Developing a new or improved design for a process, product, or service

- Defining and refining repetitive work processes

- Planning data collection and analysis to identify and prioritize problems or root causes

- Implementing changes and working toward continuous improvement

Below is an example of the most common tool used in the Six Sigma method, the fishbone diagram, to find the root causes of an effect. The six categories of the Fishbone Diagram are also known as the 6 Ms in the manufacturing world: man (People), machine, method, material, measurement, and Mother Nature (Environment).

Why Six Sigma?

Six Sigma methodologies are widely adopted across industries to streamline processes, reduce waste, and enhance product quality. By using Six Sigma, you can:

- Increase customer loyalty by delivering high-quality products and services

- Boost employee morale by creating a more efficient and supportive work environment

- Achieve significant cost savings by reducing defects and inefficiencies

Let’s do more with less and strive for excellence! Share this guide with your colleagues and friends, and consider using Six Sigma the next time you encounter a challenging problem. The Six Sigma process can be your key to achieving sustained success.